KB201C

KOMPA

Silicone material

0.2mm-3mm

7-14 days

1.3-1.8 (g/cm³)

China

ISO9001, ISO14001, ISO45001, IATF16949, EN45545-2, UL94-V0, NSF61, UL157-2007 Gaskets and Seals. CE, ROHS, PAHS, REACH

| Availability: | |

|---|---|

Product Description

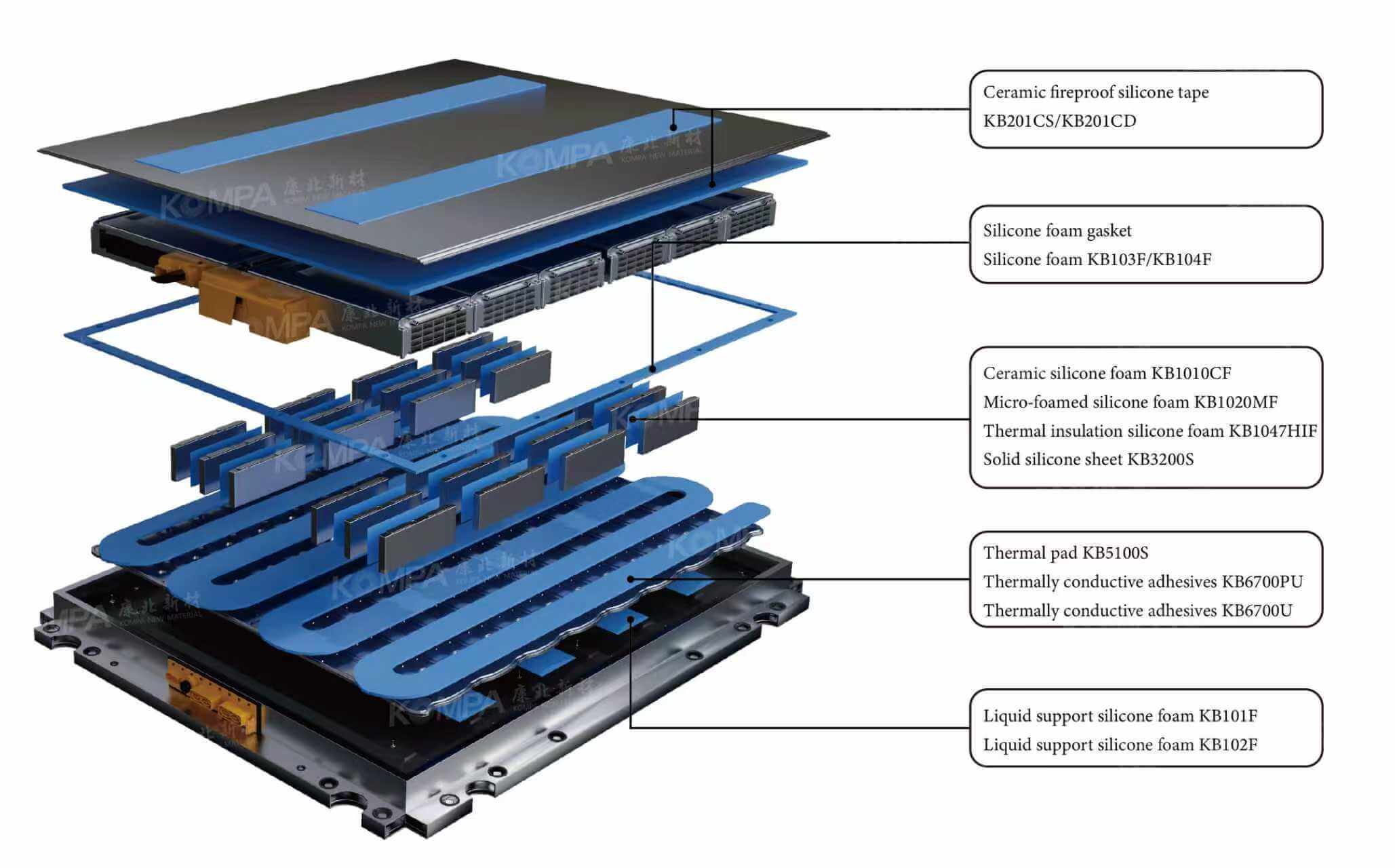

EV Battery Adhesive Tapes is a silicone-based composite material developed by KOMPA New Materials that can be ceramized at high temperatures. When this product is burned at high temperatures, its surface can be transformed into a "ceramized" hard solid, thus playing a very good role in flame-retardancy, heat insulation, and fire resistance. In order to improve the mechanical properties and the temperature resistance to burning through of this material, modified glass fiber cloth is selected as the substrate. On the premise of ensuring the bonding strength, the ceramic-silicon material can be coated on the glass-fiber-based substrate on one side or both sides, which plays the role of shock absorption, fire ablation resistance, and high-temperature insulation.

![]()

1. Exceptional Fire Resistance: Withstands direct flame at 1200°C for 30 minutes without burn-through.

2. High Insulation Retention: Maintains insulation resistance of up to 500 MΩ after exposure to 800°C for 5 minutes.

3. Certified Flame Retardancy: Complies with UL94 V-0 and EN45545-2 fire safety standards.

4. Ceramifiable Performance: Forms a ceramic-like protective layer at temperatures above 650°C.

5. Lightweight & Flexible: Retains elasticity across a broad temperature range from -60°C to 220°C.

6. Low Emission During Combustion: Features low VOC content, minimal smoke density, low smoke toxicity, and reduced heat release.

7. Environmentally Compliant: Meets RoHS 2.0 and REACH environmental regulations.

KB201C Ceramic fireproof silicone tape TDS.pdf

KB201C Ceramic fireproof silicone tape TDS.pdf

Product Model | KB201C | Testing Standard |

| Composite Material | Glassfiber | / |

| Thickness mm | 0.2-3.0 | ASTM D374 |

Density g/cm³ | 1.3-1.8 | ASTM D792 |

Hardness Shore A | 60±10 | ASTM D2240 |

| Tear Strength KN/m | ≥10 | GB/T-529-2008 |

| Tensile Strength MPA | ≥18 | ASTM D412 |

Flame Retardancy | CTM-0 or V0 | UL94 |

Thermal Conductivity W/(m.k) | ≤0.4 | ASTM E1461 |

Water Absorption Rate | ≤3% | GB/T 1034-2008 |

Operation Temperature ℃ | -60-220 | SAEJ-2236 |

| Volume Resistivity Ω·cm | 1014 | ASTM D257 |

| 800℃ Volume Resistivity Ω·cm 5min | ≥3MΩ | IEC 60243 |

RoHS2.0/ELV | PASS | RoHS2.0/ELV |

Silicone surface technology | Surface Finish: Glossy / Matte / Fabric Texture | Visual |

![]()

![]()

1. EV Battery Packs: Thermal and electrical insulation for battery modules, ensuring fire safety and containment.

2. Energy Storage Systems (ESS): Fire-resistant wrapping and insulation for battery cells and power modules.

3. Rail Transportation: Cable bundling and insulation in rail vehicles, meeting stringent fire safety standards.

4. Aerospace and Aviation: Flame-retardant insulation for wiring and components exposed to extreme temperatures.

5. Industrial Electrical Equipment: Protection of power electronics, transformers, and high-voltage components.

6. Automotive Electronics: Heat shielding and insulation in high-temperature areas of vehicles.

7. Consumer Electronics: Fireproof insulation for battery-powered devices and chargers.

![]()

To ensure product integrity and ease of handling, KB201C is packaged with care for both protection and convenience:

Supplied in rolls or sheets based on customer requirements

Each roll is wrapped with protective PE film or kraft paper to prevent contamination and damage

Packed in durable, moisture-resistant cartons for safe transit

Multiple rolls per box with interleaving layers to avoid abrasion

Heavy-duty pallets with corner protection and stretch wrap

Suitable for international shipping and warehouse storage

Each package includes clear labels with product name, size, lot number, and handling instructions

Custom labeling available upon request (e.g., client logo, barcode, etc.)

Available for industries with high cleanliness standards (upon request)

![]()

When you choose KB201C Ceramic Fireproof Silicone Tape, you're not just getting advanced thermal protection — you're getting trusted quality, customization flexibility, and full technical support.

Excellent flame resistance and thermal insulation

Uniform thickness and smooth surface for reliable application

Easy-to-handle roll or sheet format

For performance evaluation and compatibility testing before bulk purchase

Supplied in rolls, sheets, or custom die-cut parts

Thickness options from 0.2mm to 3 mm (custom on request)

Adhesive backing (single or double-sided)

Fabric or mesh reinforcement for extra strength

Ceramifiable, flame-retardant, or low-smoke formulas depending on application

PE film or kraft paper interleaved for cleanliness

Export-grade cartons or pallet packaging to ensure safe transport

Technical Data Sheet (TDS)

REACH, RoHS 2.0, UL94, and EN45545-2 compliance certificates

Engineering guidance for application, installation, and testing

Every batch is 100% inspected

RoHS/REACH compliant

Produced under ISO 9001 certified quality management systems

Let me know if you'd like to localize this for a datasheet, webpage, or brochure layout.

KOMPA is a trusted innovator in silicone-based thermal interface materials technologies. We combine materials science expertise with precision manufacturing to deliver solutions that meet the most demanding requirements in EV battery systems, energy storage, automotive electronics, and industrial applications.

Over 8 years of experience in silicone materials

In-house R&D for continuous product innovation

ISO9001-certified production with full traceability

Consistent performance, certified by third-party labs (UL, RoHS, REACH)

Tailored solutions: thickness, hardness, die-cutting

Technical support from prototype to mass production

Long-term cooperation with leading automotive and energy OEMs

Trusted by clients in Europe, North America, and Southeast Asia

Huawei – Global leader in communications, smart devices, and energy solutions

ZENERGY – Trusted supplier specializing in new energy battery systems

SAIC Motor – One of China’s largest and most innovative automotive manufacturers

Dongfeng Motor – Leading state-owned company in commercial and passenger vehicles

CRRC – World’s largest manufacturer of rail transit equipment and systems

CALB – Global innovator in lithium battery technology and energy storage solutions

Their trust speaks for our quality, reliability, and engineering excellence.

Choose KOMPA—where material innovation meets engineering precision.

To meet diverse application requirements in thermal protection and fire safety, KB201C offers flexible customization options

Available in rolls, sheets, or custom die-cut parts

Widths: up to 1000 mm (customizable)

Thickness range: 0.2 mm to 3 mm (special sizes available on request)

Single-sided or double-sided pressure-sensitive adhesive (PSA)

High-temperature resistant adhesives available

Optional fabric or mesh reinforcement for improved tensile strength and stability under heat

Standard: Gray or Red

Custom colors available for OEM/ODM projects (subject to MOQ)

Ceramifiable formulations for passive fire protection

Low-smoke, low-toxicity, halogen-free versions

Electrically insulating or thermally conductive grades available on request

Smooth or textured surface for better adhesion or handling

Protective film or release liner (if adhesive-backed)

RoHS 2.0 / REACH compliant

UL94 V-0 and EN45545-2 rated versions available

Custom formulations to meet project-specific standards

Let me know if you'd like to convert this into a table for your website, catalog, or technical datasheet.

Ceramic Fireproof Silicone Tape KB201C is used for thermal insulation, flame protection, and electrical safety in high-temperature and fire-critical environments. It is specifically engineered for applications that demand ceramifiable behavior, low smoke toxicity, and high-temperature insulation stability. Thanks to its advanced silicone-ceramic formulation and fire-retardant properties, KB201C is ideal for

Acts as a thermal and fire barrier between battery cells and modules

Provides cable insulation and bundling with compliance to EN45545-2 fire safety standards

Ensures insulation performance under thermal shock or flame exposure

Offers lightweight, flexible fire protection for wiring and sensitive components

Serves as protective wrap or spacer in furnaces, ovens, and heat zones

Its ability to ceramify above 650°C and maintain electrical insulation at high temperatures makes it a dependable material for passive fire protection. KB201C helps prevent fire propagation, reduces risk during thermal events, and supports compliance with strict safety standards.

Yes, Please download here

Selecting the right version of KB201C depends on your specific application needs. Consider the following factors to ensure optimal performance:

For applications exposed to extreme heat (above 650°C), choose ceramifiable grades for added fire barrier performance.

For continuous high temperatures below 300°C, standard fire-retardant grades may be sufficient.

Available thickness: 0.5 mm to 3 mm

Thicker versions offer better thermal and electrical insulation but may be less flexible.

Thinner versions are ideal for tight spaces or lightweight designs.

If insulation performance under fire is critical (e.g., EV batteries, power systems), ensure the grade maintains >500 MΩ after heat exposure.

Choose between rolls, sheets, or custom die-cut parts based on how you plan to install the tape.

Die-cut shapes reduce labor and improve fit for mass production.

Optional PSA backing (single or double-sided) for easier assembly.

High-temperature adhesives are recommended for flame-exposed areas.

For transportation and public safety systems, confirm compliance with UL94 V-0, EN45545-2, RoHS, and REACH.

Custom certifications available upon request.

If low smoke, halogen-free, and non-toxic performance is a priority, select low-VOC and low-smoke emission grades.

Contact our technical team for expert guidance and sample testing. We're here to help you choose the right solution for your project.

+86 18961262135

No. 35 Ziwei Road, Zhonglou District, Changzhou, Jiangsu Province, China